Imagine living and working in spaces surrounded by walls that are gradually freezing and thawing throughout the day in response to exterior temperatures. Sound crazy? Well, phase change material (PCM) is an emerging technology that uses this process to reduce energy consumption in buildings and passively regulate indoor temperatures.

This raises an important question for us at LHB: can PCMs make an impact on energy consumption here in Minnesota? Members of the research team at LHB have been conducting a simulation study of PCMs with our colleagues at Slipstream to find the answer to this question.

What is a phase change material?

A phase change material (PCM) is any material that uses the latent energy potential of a phase change to store and release thermal energy. In buildings, PCMs are used to stabilize indoor air temperatures, decrease energy consumption, and shift peak energy loads.

How does it work?

Phase change materials are more common than you might think! The most common form of PCM is water. Just like the ice in your cooler, PCMs in buildings slowly melt as the indoor temperature rises. When a frozen PCM reaches its melting point, it begins to absorb heat without rising in temperature. This heat is called latent energy, which is the amount of energy required to change the material from a solid to a liquid.

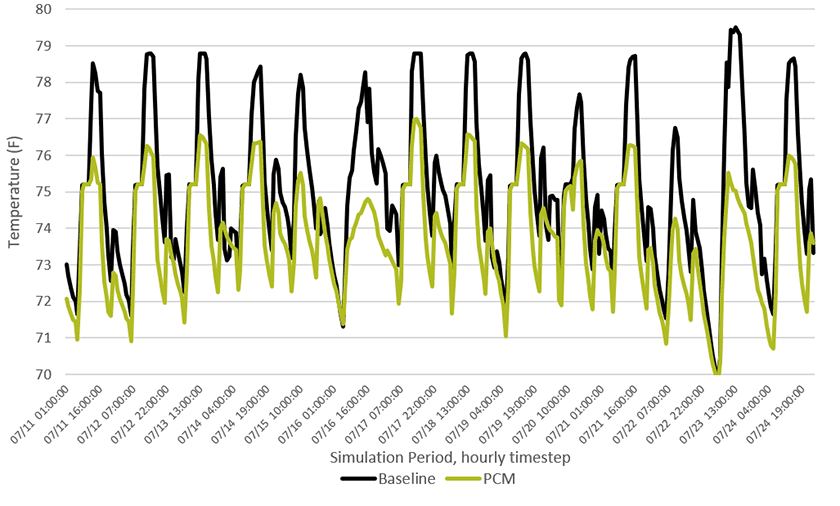

PCMs used in buildings – which are typically comprised of paraffins, salt hydrates, or organic substances – are engineered to melt at the desired room temperature. The room does not rise above this temperature until all the PCM has melted. (“Potential Energy Savings due to Phase Change Material in a Building Wall Assembly: An Examination of Two Climates”)[i] Once the room’s temperature drops below the PCM’s freezing point – typically at night – the PCM will begin to solidify, releasing the thermal energy stored throughout the day back into the space.

What do the results say?

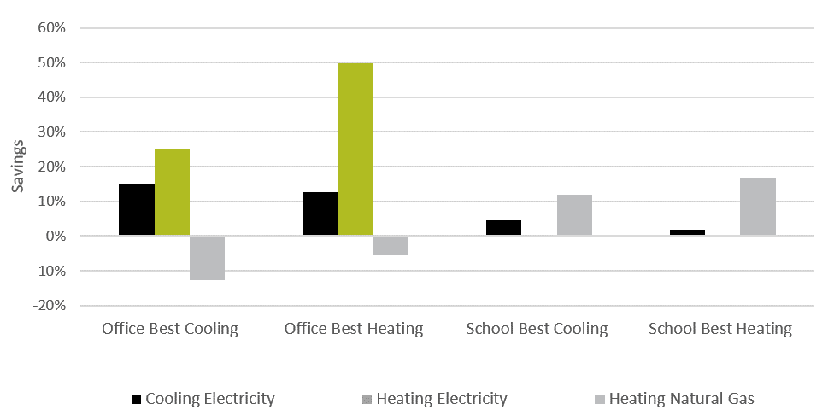

Our study found significant energy savings potential for commercial buildings in Minnesota. As you can see in figure 1, optimized PCM applications achieved savings of up to 15% of cooling energy, 50% of heating electricity, and 17% of heating natural gas. This amounts to a 5% reduction in total building energy, with a peak electricity demand reduction of 4-7%.

What other benefits are there?

So, we answered our initial question about energy consumption, but what else can PCM provide? Using PCM to passively regulate indoor air temperature in buildings has the potential to:

- Reduce annual energy consumption, along with its associated costs and greenhouse gas emissions.

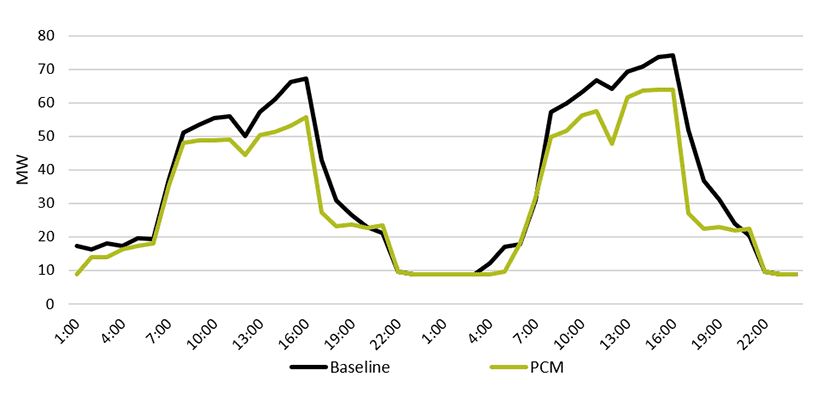

- Reduce peak demand for electricity and shift demand to off-peak hours. This helps balance electricity supply and demand, resulting in lower energy rates where peak demand pricing applies.

- Improve thermal comfort of building occupants, which can increase productivity and satisfaction.

- Reduce energy demand on existing HVAC systems, lowering operating costs and wear on the equipment. (“Phase Change Materials and Thermal Energy Storage for Buildings”)[ii]

- Eliminate the need for installing costly HVAC equipment (e.g. air conditioning) in existing buildings by passively improving thermal comfort. (“Using Phase Change Materials to Reduce Overheating Issues in UK Residential Buildings”)[iii]

- Increase resilience and passive survivability by maintaining safe thermal conditions when power is unavailable.

Where should PCMs be used?

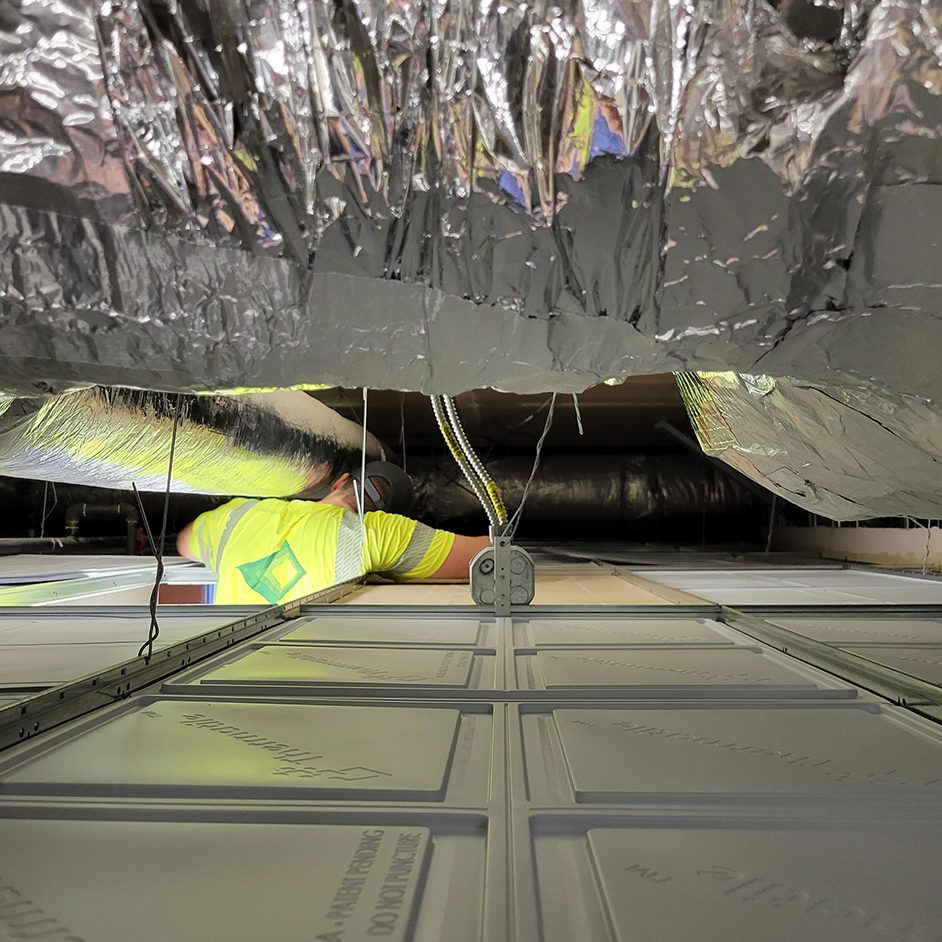

PCMs will provide benefits in buildings that have high occupancy rates throughout the day and have high internal loads, such as offices, computer labs, and data centers. (“Phase Change Materials: Are They Part of Our Energy Efficient Future?”)[iv] Other beneficial applications for PCMs are older buildings with poorly performing thermal envelopes that operate HVAC systems at peak capacity to maintain interior temperature setpoints. PCM can be installed within wall, roof, or ceiling assemblies in new construction. For non-invasive retrofits, PCM can be installed above suspended ceilings (this was the condition studied in our report).

What now?

Based on the results of our report, it seems that phase change materials are a cost-effective way to make our buildings more resilient, responsible, and sustainable. Since this technology is relatively new to the market, it is our responsibility at LHB to become advocates for change, pushing ourselves and our profession to recognize these opportunities and implement them to the best of our ability.

[1] Childs, Kenneth and Therese Stovall. March 2012. “Potential Energy Savings due to Phase Change Material in a Building Wall Assembly: An Examination of Two Climates.” Energy and Transportation Science Division. pp 1-35.

[2] Cabeza, Luisa F. and Alvaro de Gracia. September 2015. “Phase Change Materials and Thermal Energy Storage for Buildings.” Energy and Buildings. Vol 103. pp 414-419.

[3] Auzeby, Marine; Chen, Chao; Buswell, Richard; Ling, Haoshu; Ng, Bobo; Pan, Song; Tindall, Jess; Underwood, Chris; Wei, Shen. 2017. “Using phase change materials to reduce overheating issues in UK residential buildings.” Energy Procedia. Vol 105. pp 4072-4077.

[4] Delaney, Paul; James, Brian; Southern California Edison. 2012. “Phase Change Materials: Are They Part of Our Energy Efficient Future?” ACEEE Summer Study on Energy Efficiency in Buildings. pp 3-160-3-172. Published by Southern California Edison.

This project was supported by a grant from the Minnesota Department of Commerce, Division of Energy Resources, through the Conservation Applied Research and Development (CARD) program, which is funded by Minnesota ratepayers.