Phase change materials (PCMs) are used for many different applications, from refrigeration to textiles.

In the building industry, PCM has drawn attention due to its ability to reduce thermal energy transfer at a level of 4 to 20 times that of standard insulation. Especially as Minnesota gets closer to its carbon-neutrality goals, strategies that can store and release thermal energy are increasingly important to the system-wide energy transition; this material has a lot of potential.

However, with literature limited on PCMs as a passive thermal strategy, LHB partnered with the nonprofit energy organization Slipstream to conduct a Conservation Applied Research and Development (CARD) study. When the study began in 2019, PCMs were commercially available for building applications but were not commonly used in either new construction or renovation projects, and no studies on their performance had been conducted in climates like Minnesota. The primary aim of this research was to assess the technology’s impact on energy efficiency in Minnesota buildings. PCMs impact on occupant comfort, as well as their feasibility, cost-effectiveness, and statewide savings potential, were also investigated, and the project team used this knowledge to make recommendations for user adoption and further study.

The project was divided into two phases, a simulation study (Phase I) and a field study (Phase II), both conducted by LHB and Slipstream. Based on many attributes including evidence of energy savings potential for PCM in building applications, the Phase I findings indicated that PCM could bea candidate for a broad utility program offering. The simulation study concluded in March 2020 with the decision to proceed with a field study. Due to unforeseen impacts of the COVID-19 pandemic, Phase II was delayed until spring 2021.

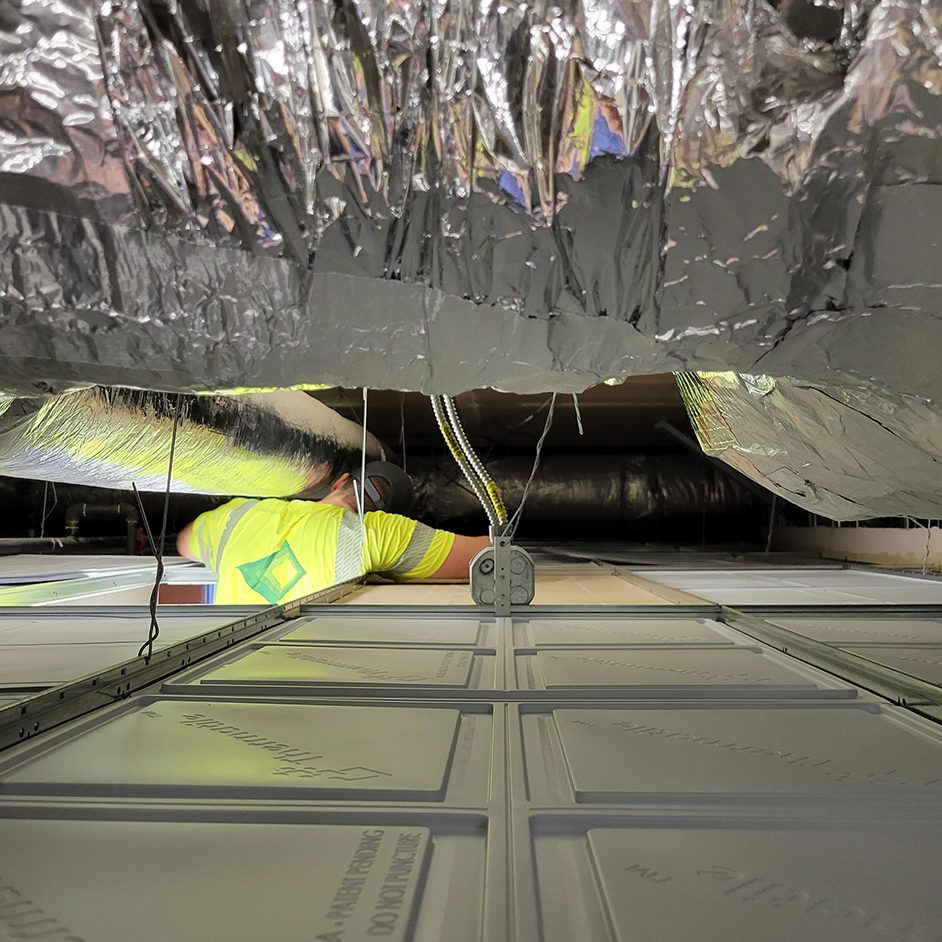

Phase II focused on the collection and analysis of energy data at two Minnesota banks. The study tracked baseline energy data prior to retrofitting the buildings with above-ceiling PCM tiles branded as “Templok.” Following a year of data collection, the team analyzed the effect of PCMs on energy consumption for this office/retail building type. The heating and cooling savings were then used to conduct a life cycle cost analysis. Key challenges and opportunities for market adoption were distilled based on the team’s experience with the retrofit process. These findings informed the team’s conclusions and recommendations for the application of phase change material in Minnesota utility programs.

The field study headline: the findings did not provide conclusive evidence that installing PCM above the suspended ceilings in the study sites resulted in heating or cooling energy savings. This is due to several uncontrolled variables that affected the efficacy of the PCM and made its impacts difficult to isolate. Although PCM in this application is a passive technology, it became evident that well-controlled HVAC systems are an important tool to create the temperature gradients for the PCM to reliably experience complete phase changes.

Just as the Phase II report was being finalized, Armstrong World Industries purchased the Templok family of products and launched a new “Energy Saving Ceilings” line by incorporating Templok into their acoustic ceiling tile product line. Armstrong’s ceiling tile products are well-known in the design and construction industry, and this change in distributor and integration into a commonly used product (acoustic ceiling tiles) will make above-ceiling PCMs accessible to a broader audience.

View project findings including the Phase I and II reports and fact sheets are here. ■