Imagine you could build a stick-framed exterior wall that prevents air infiltration and water vapor migration. Maybe it also includes sheathing that supports exterior cladding without hitting the studs. And what if you could eliminate condensation within the stud cavity and reduce the number of assembly steps? Impossible? Not necessarily, says LHB’s Housing team.

In fact, the continuous insulation panel technology used in Skyridge Flats, an LHB-designed project in Duluth, helps do all that—and the approach may soon become the standard on stick-frame construction. The so-called Awesome Wall approach will not only keep the 70-unit senior housing facility warm and dry inside, architect Andy Madson says, it will also reduce energy bills and allow the project to meet the requirements of Energy Star Multifamily New Construction. (ESMNC is the stringent energy-related standard recently adopted by Minnesota Housing Finance Agency.)

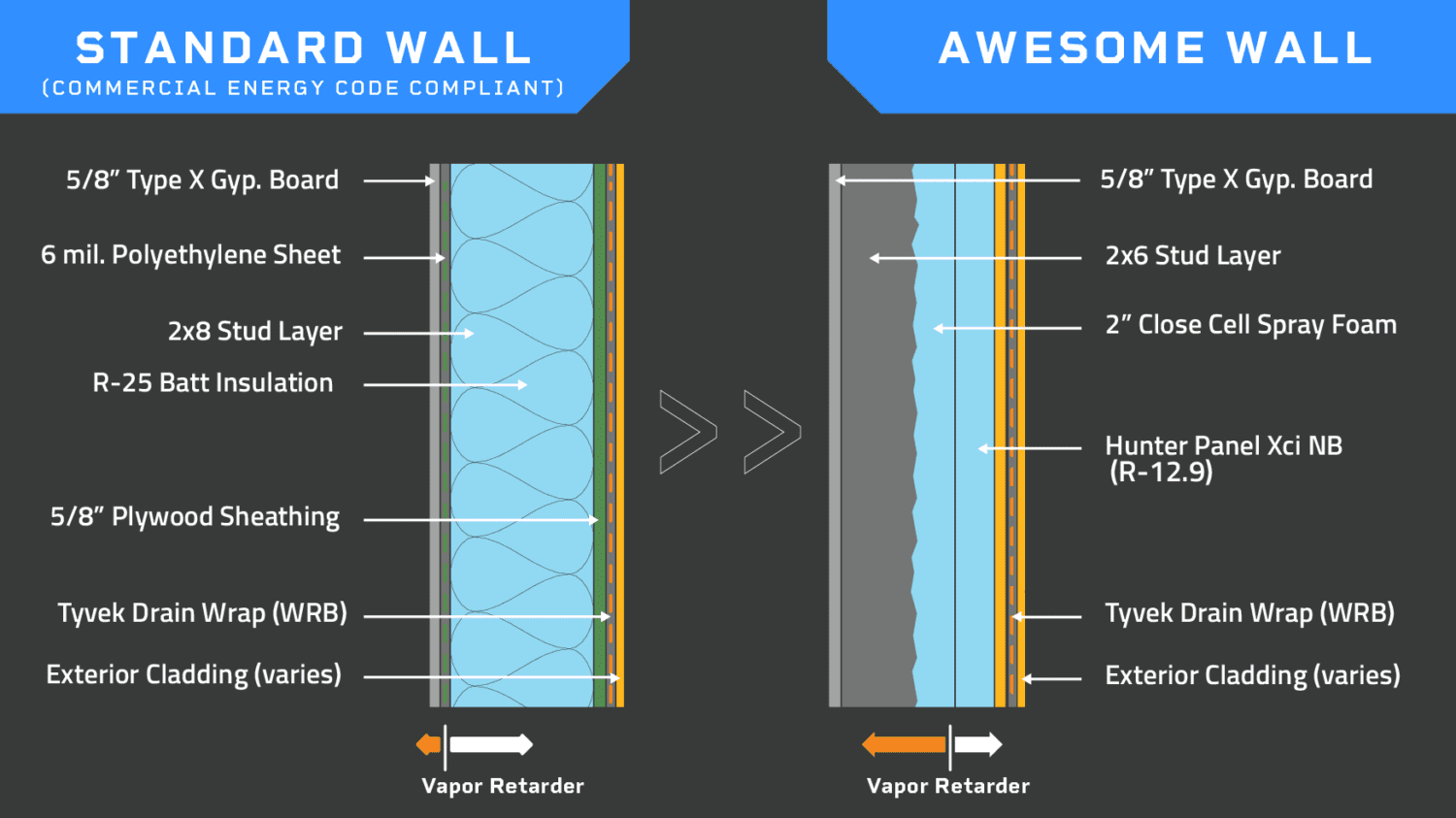

Traditional insulation methods in stick-framed construction have typically called for filling the space between studs with insulation, then adding a vapor barrier to the interior side of the stud. But mold can be a problem with this approach—a result of condensation in the stud cavity.

In Awesome Wall construction (see diagram), rigid foam continuous insulation wall panels are fastened to the exterior side of the stud. Next, closed-cell spray insulation is applied directly to the interior side of the insulated panel within the stud cavities. The result is an assembly that thermally breaks the conductive path of the sheathing to the studs. In Minnesota’s climate, the ideal balance point is to match the R-value of the continuous insulation with the cavity insulation to keep the condensation point of the wall within the continuous insulation layer. This leaves moisture nothing to condense to and eliminates mold.

“We’ve analyzed the efficiency and building science of numerous assemblies, and the Awesome Wall has risen to the top.”

Andy Madson, LHB senior architect

No separate vapor retarder is required, either, as the closed-cell foam does double duty as a vapor barrier. The wall cavity is left mostly empty, making it easy to install wiring without puncturing the vapor barrier or compromising the thermal characteristics of the wall.

Initial analysis by LHB staff suggests that Awesome Walls are easier to assemble, have a higher U factor, produce superior HERS ratings, and exceed current energy code requirements. Materials and installation also cost a bit more—but pricing may drop if the technique becomes more widely used and wall-panel manufacturers choose to fasten the continuous insulation panels to the framing within the factory.

Within the Housing Studio, Madson predicts, Awesome Wall construction will soon be the standard for stick-framed projects rising four floors or higher. “Architects are constantly reacting to ever-changing energy codes,” Madson says. “We’ve analyzed the efficiency and building science of numerous assemblies, and the Awesome Wall has risen to the top. By reaching beyond the current code benchmark, our studio is proactively providing increased benefit to our clients.” ∎