Line Reversal

Change of service and flow reversal

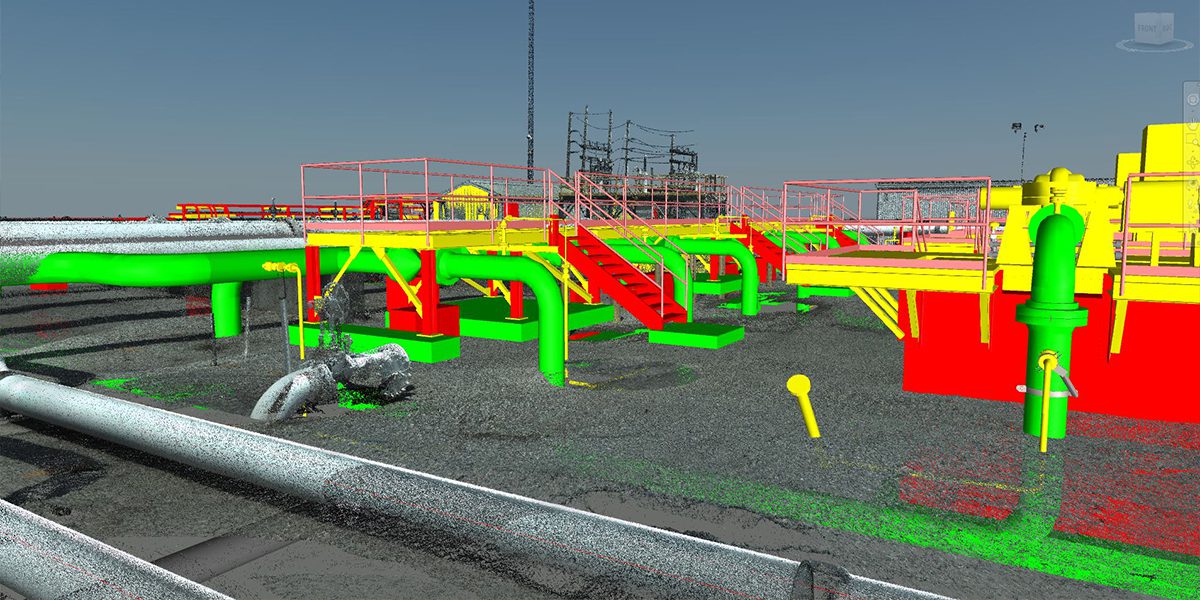

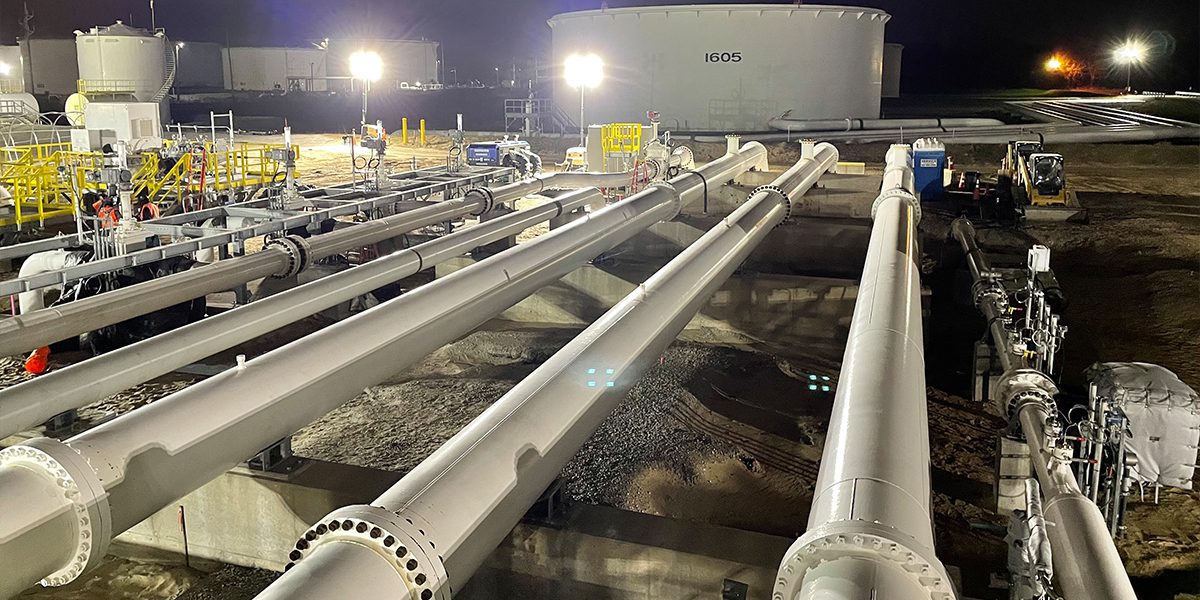

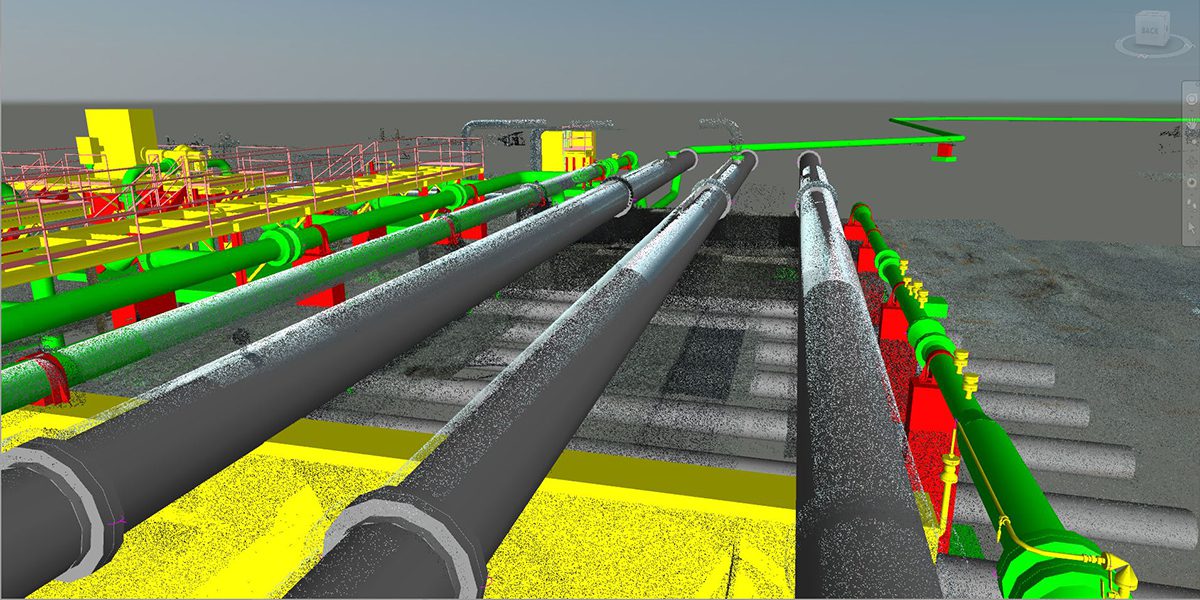

This project took the previously idled pipeline and reversed the flow so that product could be transported between terminals. To accommodate the reversal of flow, modifications were required at the terminals on both ends of the pipeline and at the two intermediate pump stations on the line. Modifications at the first terminal included design of a new originating pump station, transient overpressure protection system, replacement of existing terminal transfer line piping, and electrical infrastructure upgrades. Modifications at the second terminal included design of new delivery pressure control infrastructure, transient overpressure protection system, and various upgrades to allow receipt of product at the facility. Modifications to the two intermediate stations included piping crossovers for the station inlet and outlet piping and flow meter replacements.

LHB staff provided a variety of services over the three year duration of the project. LHB assisted with project scoping and development, completed survey and detailed engineering design for the facility modifications, provided construction support services, and completed project closeout drawings.

Transient Overpressure Protection System

LHB designed transient overpressure protection systems based on recommendations provided by third-party transient hydraulic studies at both terminals on either end of the pipeline. With every transient system design, a detailed pipe stress analysis is completed using CAESAR II software with forces of the relief event accounted for in this analysis. Our structural and mechanical engineering groups work together to ensure the system has the right balance of restraint and flexibility. LHB provided the structural, mechanical and electrical engineering services and specified the material to be purchased for these systems.

Reused Equipment and Field Engineering Support

To minimize project costs, our client asked that as much equipment and buildings be reused as possible, so equipment was removed and relocated between sites to accommodate the line reversal which presented engineering and construction sequencing challenges. The adjacent image represents one challenging installation of electrical switchgear in an existing building. Throughout construction LHB provided on-site field engineering support to help expedite the resolution of issues found during construction.