Wood, a classic building material, has seen a resurgence in recent years. Timber-framed commercial buildings are touted as emblems of sustainability, and wood is increasingly extolled as a tool for fighting climate change.

Dozens of cities around the world, from Portland and Lyon to Tokyo and Adelaide, have welcomed wooden structures or approved their construction in recent years. In 2022, Ascent MKE, a newly opened 284-foot apartment tower in Milwaukee, officially became the world’s tallest wood structure. But that record may fall any day now: Last fall, developers in Perth, Australia, announced plans to build a 627-foot-tall timber-framed tower, which, if completed, would dwarf all existing and proposed competitors.

Wood offers a unique set of advantages as a building material. Its exceptional strength-to-weight ratio enables the creation of resilient yet lightweight structures. Its natural thermal insulation properties contribute to energy efficiency, minimizing the need for additional insulation. It’s a renewable resource, and in sustainable design, when appropriate, timber construction can replace concrete and steel, whose production generates an outsize amount of climate-warming gases.

Sustainably managed forests also remove carbon dioxide from the atmosphere and sequester it in the wood. When we use wood in buildings, we remove it from the atmospheric carbon cycle and create stable carbon reservoirs. Other benefits of sustainable forests include enhanced wildlife habitat, improved water quality, and local temperature regulation.

From logs to laminates

Wood is a significant component of three LHB projects currently in development. Designers often love wood for its aesthetics, but in these instances, client sustainability goals drove our exploration and experimentation with wood. As you’ll see, we successfully integrated wood into the design of all three projects, but each called for a slightly different approach: the exact materials ranged from timber frames to wood panels to glue-laminated timber (also known as glulam).

North House Folk School

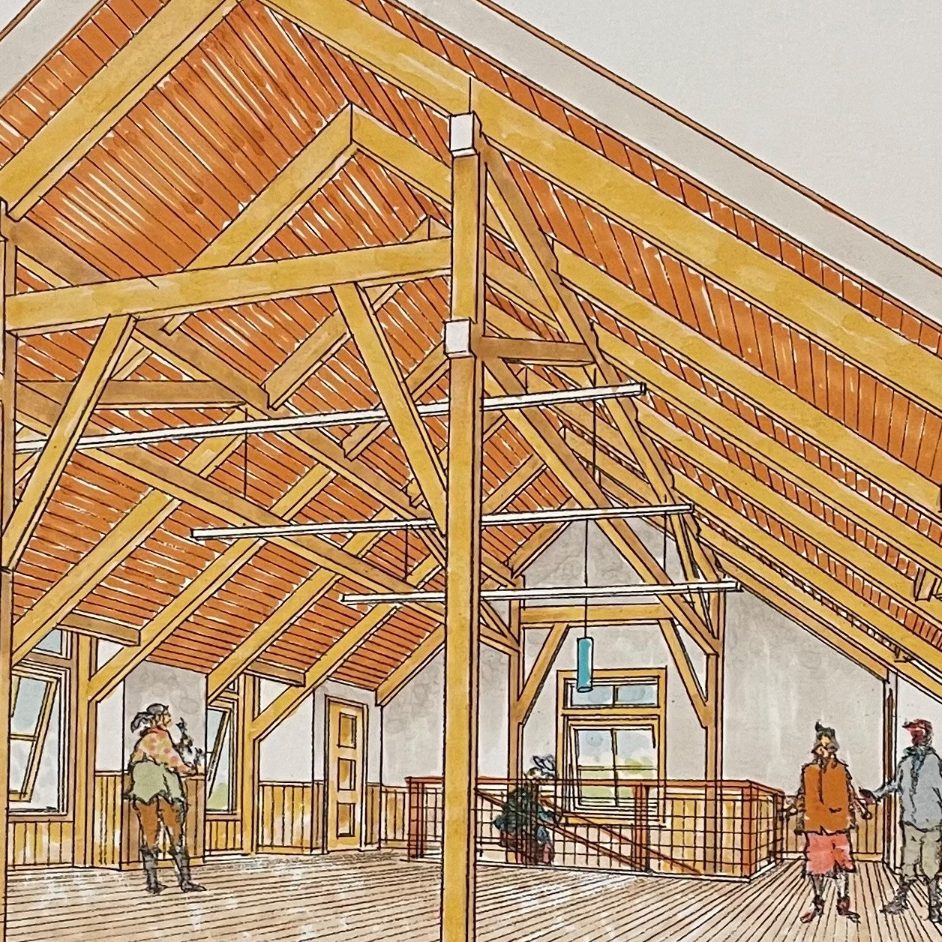

Based in Grand Marais, MN, North House Folk School offers classes in a wide range of traditional crafts and skills, including timber framing. So it’s not surprising that after the school’s board retained LHB to design a 6,000 SF welcome center, including classrooms, administrative offices and a store, the idea of building with locally hewn timber soon surfaced. With wood sourced from sustainable forests in the region and milled locally, the North House community reasoned that timber framing could benefit both the planet and local economy. It would also show off the skills of local craftspeople.

The process of timber framing is often slower than traditional stick construction, because beams have to be hand-carved. But it goes up quite quickly once the pieces are trimmed. Rot, bugs, and fire are often a concern with wood, but simple precautions can reduce risks associated with all three. Plus, timber-framed buildings are inherently fire resistant: When the surface is charred, an insulating layer is formed, protecting the underlying material. From a fire-hazard perspective, timber structures can be just as safe as those made with non-wood materials.

Mt. Telemark Village

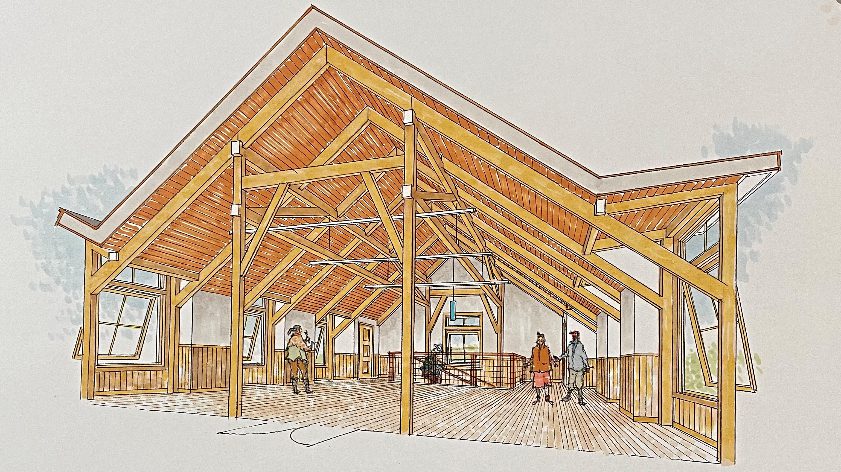

Glulam beams and columns are key elements in Base Camp at Mt. Telemark Village, a 12,000 SF center for silent sports being built in Hayward, WI, by the American Birkebeiner Ski Foundation. When strips of wood are layered and bonded with adhesive, the result is a super-strong and resource-efficient material that can be used in numerous structural applications. What’s more, the material still has the warmth and luminescence of wood.

Glulam proved the right solution for the design of Base Camp for two reasons. The interior spaces needed to be spacious and open to accommodate large groups. Timber construction would have required the use of several additional columns to support the wood beams, whereas glulam beams can be manufactured at astonishing lengths. And given the desired aesthetic for Base Camp—think alpine ski lodge or national park visitor center—wood was an excellent choice: its natural aesthetic helps the building blend with the rural environs that surround the building.

A1X Automation

This 25,000 SF office and light-manufacturing facility will be part of the Heights, a net-zero community being developed in east St. Paul. Roughly 25 workers will be employed by the business, which produces custom electrical panels, integrated robotics, and custom machinery.

To reduce the amount of embodied carbon in the structure, the owner asked LHB to investigate wood construction. As such, the building will be made of prefabricated insulated wood tilt-up panels. In addition to embodied carbon benefits, the panels provide better insulation and offer fewer thermal breaks than traditional concrete panels. Additionally, since the wood panels are lighter than concrete tilt-ups, less heavy equipment, like cranes, will be required for installation—a significant cost savings. It also requires a significantly smaller foundation, resulting in less use of CO2-producing concrete.

Wood may not be right for every project, of course. But it’s surprisingly versatile, eco-friendly, adaptable, and strong, and as our climate changes and sustainably sourced, carbon-embodying materials becomes a top priority for all of us, it certainly deserves a second look. ∎

Want to reduce the carbon footprint and increase the ecological benefits of your next building? Contact LHB architect Stacee Demmer.