David is the Mechanical Lead at LHB and has 32 years of mechanical design experience. His duties include overseeing design and specification of building MEP systems, forensic engineering services, sustainable project consultation, and in-house training. His specialties include solar energy systems, unique/special system design, and sustainability. In this interview, David shares his thoughts about sustainability and the future of mechanical engineering.

Opposition to green building practices cite cost as a major deterrent. In your opinion, how can we make sustainable design solutions more affordable?

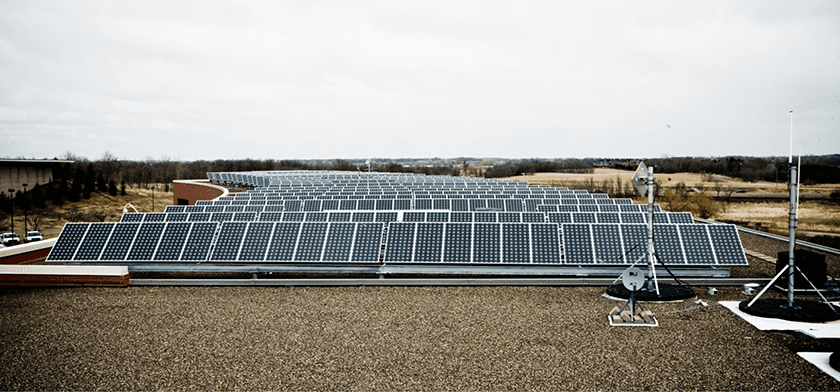

There are plenty of things that could be done more sustainably that costs us nothing, or nearly nothing, that we do not do today. Generally, in LHB’s practice, we have done most of our successful work, in terms of sustainability, based on very economic building design. I think about Cascade Meadow, one of our signature projects which was also a very high dollar project, and it performs very well – but in terms of investment per energy spent, I think some of our K-12 Education projects exceed that. They have saved more energy because they are larger and serve more people, and yet were done for less than average cost. To me, that’s good design.

I don’t buy the argument that green building costs more.

How could we spread that message?

Unfortunately, we are probably at the stage where we can only interact and engage with the people who are our clients, and I think it’s difficult for us to go outside that area. There are reasonable things that can be done and we just need to talk to people about the options that will impact their business and their energy use going forward. In doing so, you need to be able to count your argument in a way that others can understand you. It is very easy to start speaking at a higher-level language, but you can still explain what you’re trying to do without talking down to your clients.

What major barriers do you run into when implementing sustainable measures into a project?

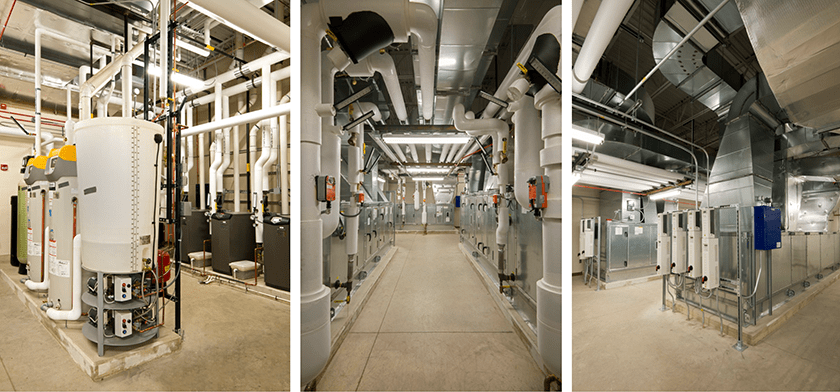

The problem with mechanical and electrical systems is that for them to be the most effective, they should be fully integrated with the architecture. For this to happen, it’s extremely important to make sure that we have a fully integrated team that can bring it all together into one cohesive structure. The K-12 Education team has had very successful low to no-cost sustainability projects because of how involved our ME group is from the start.

In the commercial and housing teams, these groups are trying to integrate our mechanical and electrical expertise while working with the design-build delivery concept, making it a little more challenging because these ME systems are often driven by cost and not necessarily by what is best for the energy profile of the building. So, we have some work to do to optimize the integration of our mechanical and electrical knowledge in these groups.

What skills do you think will be the most needed in the future for mechanical engineers?

You’re going to have to be innovative in the way you approach a problem so that you don’t do it all by brute force. It is all a question of finesse and managing expectations. We know brute force works, but to me brute force is not sustainable – it’s using more resources than you need to get the job done.

The other difficulty moving forward is being able to project and understand what will happen to our climate and the world around us. If you are designing a building with a 50-year life span, and if at 25 years you’re going to have to change the mechanical system, how are you accounting for that? What are you doing to make that building adaptable? These questions don’t always rise to the level where you can bring it up to a client. We aren’t thinking of this now and I think that it will be critical to do and know going forward. There are very few people that specialize in this area of mechanical engineering, so hopefully we get the best and the brightest to do it.